-43%

Power Supply

Power Supply

Electronic Components

Electronic Components

Ai Thinker ESP Wifi Modules

Ai Thinker ESP Wifi Modules

Current Sensors

Current Sensors Drone Parts

Drone Parts IoT & Wireless

IoT & Wireless

E-Bike Parts

E-Bike Parts

Mechanical components

Mechanical components

Note:

Hurry and get discounts on all Raspberry Products up to 20%

IBOTS1000

₹189.00 Original price was: ₹189.00.₹107.00Current price is: ₹107.00.

Available on backorder

Available on backorder

Free

₹75 for parcels below 1 Kg and ₹100 for parcels weighing between 1 Kg to 2 Kg.

2-3 Days

₹75

₹125 for parcels below 1 Kg and ₹175 for parcels weighing between 1 Kg to 2 Kg.

2-3 Days

₹125

₹250 for parcels below 1 Kg and ₹325 for parcels weighing between 1 Kg to 2 Kg.

2-3 Days

₹250

Our courier will deliver to the specified address

2-3 Days

Rs. 99

Payment Methods:

1. Order the Product and Specify the Delivery Method

2. You Will Receive an Order Confirmation Message

3. Wait for Your Order to Arrive

4. Pick up Your Order at The Checkout Area

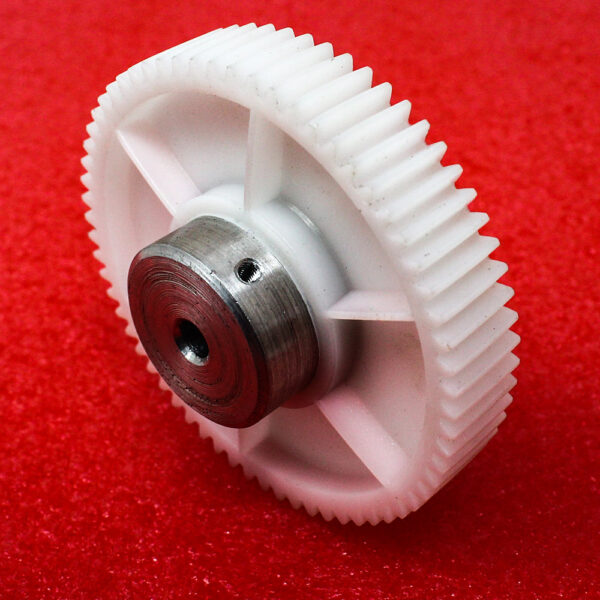

A 15 teeth plastic spur gear specified as 1M-15T-6-15 is a commonly used gear in various mechanical and robotic applications. Here’s a detailed overview of this gear, including its features, applications, and benefits:

Only logged in customers who have purchased this product may leave a review.

Categories

Useful Links

Useful Links

Power Supply

Power Supply

Electronic Components

Electronic Components

Ai Thinker ESP Wifi Modules

Ai Thinker ESP Wifi Modules

Current Sensors

Current Sensors

Drone Parts

Drone Parts IoT & Wireless

IoT & Wireless

E-Bike Parts

E-Bike Parts

Mechanical components

Mechanical components

No account yet?

Create an Account

Available on backorder

Reviews

Clear filtersThere are no reviews yet.