- Pick up from the IBOTS Store

Free

- Delivery Charges: Tamil Nadu

₹75 for parcels below 1 Kg and ₹100 for parcels weighing between 1 Kg to 2 Kg.

2-3 Days

₹75

- Delivery Charges: Other South India

₹125 for parcels below 1 Kg and ₹175 for parcels weighing between 1 Kg to 2 Kg.

2-3 Days

₹125

- Delivery Charges: North India

₹250 for parcels below 1 Kg and ₹325 for parcels weighing between 1 Kg to 2 Kg.

2-3 Days

₹250

- Courier delivery

Our courier will deliver to the specified address

2-3 Days

Rs. 99

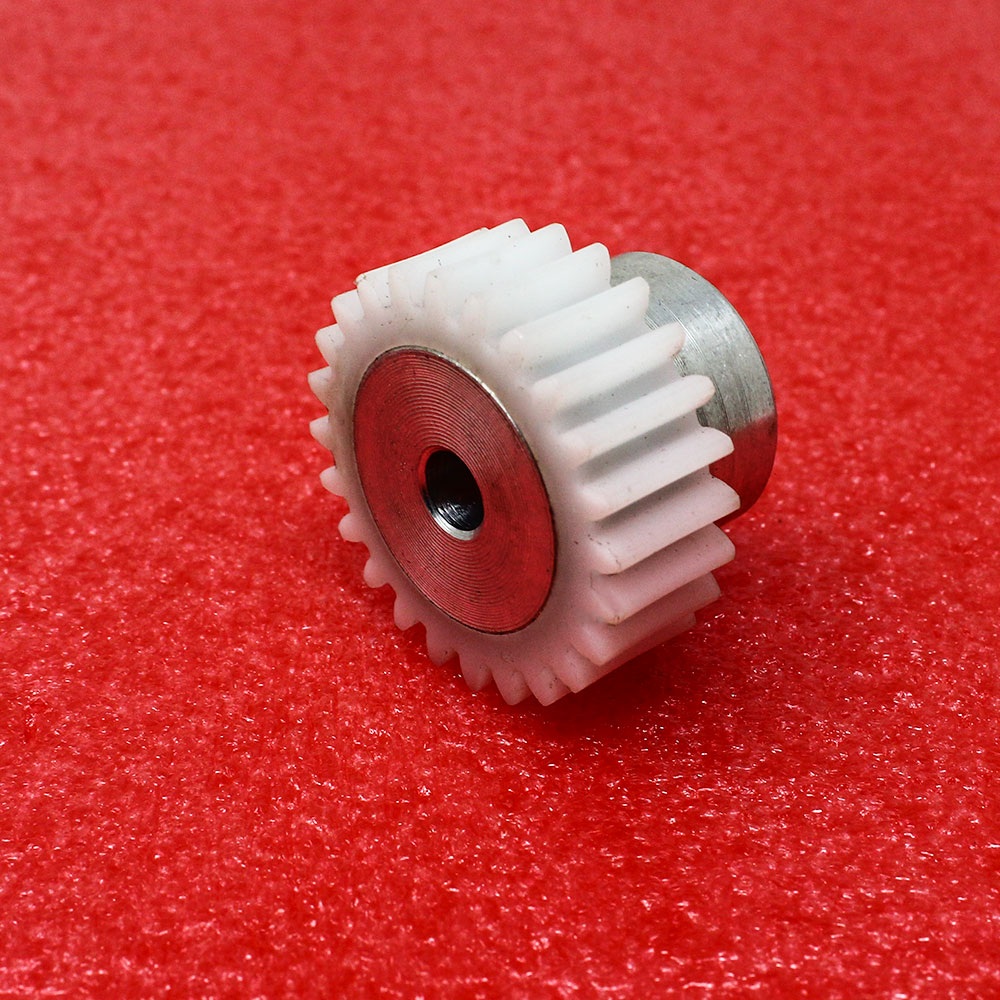

Motors

Motors

Reviews

Clear filtersThere are no reviews yet.